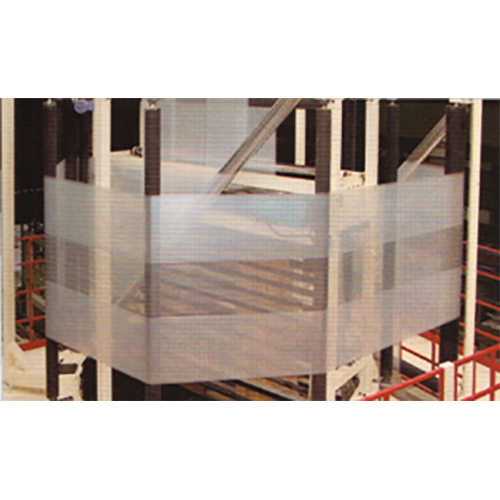

ABC Type SEPL Three Layer Blown Film Plant

Price 7500000.0 INR/ Unit

ABC Type SEPL Three Layer Blown Film Plant Specification

- Efficiency (%)

- 100

- Production Capacity

- 150 Kg

- Country Of Origin

- INDIA

- Usage & Applications

- Industrial Use

- Speed

- 60 mm/m

- Frequency

- 50 Hertz (HZ)

- Motor Power

- 75 Horsepower (HP)

- Model No

- SEPL TLRH ABC

- Type

- Three Layer Blown Film Plant

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Power

- 75 Horsepower (HP)

- Weight (kg)

- 6 Tonne

- Color

- White And Yellow

- Warranty

- 1 Year

- Capacity

- 150 Kg/hr

- Features

- High effeciency

- Surface Finish

- Coated

- Machine Type

- Three Layer Blown Film Plant

- Power Consumption

- 220 Volt (V)

ABC Type SEPL Three Layer Blown Film Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- INDIA

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1

- Sample Available

- Yes

- Packaging Details

- Standard Packing

- Main Export Market(s)

- Asia, North America, South America, Eastern Europe, Western Europe, Australia, Central America, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO, IEC

About ABC Type SEPL Three Layer Blown Film Plant

NOTE:- Price Will Be Very On Customisation Of Products.1. Description

A Three Layer Blown Film Plant is a co-extrusion film line with three extruders feeding a three-layer die (ABA/ABC configuration). It produces multilayer polyethylene (PE) films with enhanced barrier, strength, and performance compared to single layer lines.

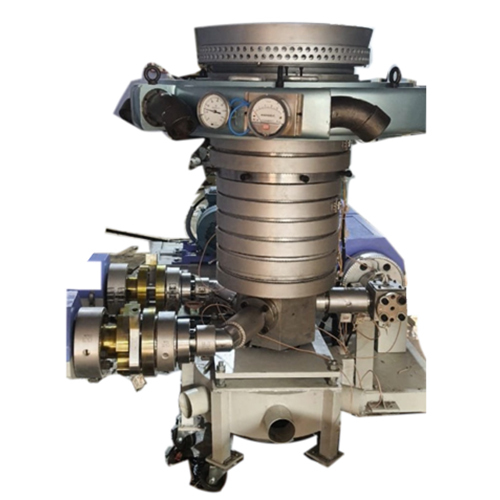

2. Extrusion System

Extruders

-

Number: 3 extruders (A/B/C) for co-extrusion.

-

Screw diameter: typically 45 mm 120 mm (customizable).

-

L/D Ratio: approx. 28:1 32:1.

-

Barrel & screw: nitrided / bi-metallic for wear resistance with grooved feed.

-

Heating Zones: multiple PID controlled heating zones on each extruder.

Drive System

-

AC motor drives with variable frequency drives (VFD) for speed control.

-

Gearbox: helical type with built-in bearings.

3. Die & Cooling

-

3-Layer Co-extrusion Die: Spiral or ABC type for uniform melt blending.

-

Die diameter: typically 150 mm 300 mm or as per width requirement.

-

Air Cooling Ring: Dual-lip or IBC (Internal Bubble Cooling) preferred for uniform thickness and stable bubble.

-

Auxiliary heat exchanger & blower included.

4. Film Output & Quality

Output Capacity

-

Typical range: 50 kg/h 650 kg/h, depending on extruder size and configuration.

Film Properties

-

Thickness range: 10 300 m (most commonly 20 150 m).

-

Layflat width: 200 mm 2700 mm+ depending on model and die size.

-

Gauge control: 5 % (typical) using auto thickness measurement systems.

5. Film Take-Off & Winding

-

Haul-off units: Adjustable speed haul-off with oscillating platform optional for gauge randomization.

-

Winder: Surface or pneumatic rewinder, single/dual station.

-

Options: centre slitting, side trimming, web aligning.

6. Control & Automation

-

PLC Touchscreen control system for monitoring and adjustments.

-

Optional features include:

-

Gravimetric dosing system (for precise resin feed).

-

Auto thickness & width measurement.

-

Recipe storage and supervisory control panel.

-

7. Material Compatibility

-

Primary Polymers: LDPE, LLDPE, HDPE, metallocene resins.

-

Others: EVA, biodegradable compounds, compound blends.

8. Typical Plant Utilities

-

Power: 3-phase 380415 V supply.

-

Compressed air: 6-8 bar for blowers/control valves.

-

Cooling water/air: for cooling tower / chillers.

9. Optional Add-Ons

-

Corona treater for improved printability.

-

Gravimetric dosing & blending for precise melt composition.

-

IBC system for superior bubble cooling and film properties.

-

Auto winding & thickness control systems.

10. Example Specification Snapshot (Typical)

| Parameter | Typical Value |

|---|---|

| Extruders | 3 (45-120 mm dia) |

| Screw L/D | 28-32:1 |

| Film Width | 200 2700 mm |

| Thickness | 20 150 m |

| Output | 100 650 kg/hr |

| Cooling | Dual-lip / IBC air ring |

| Control | PLC & touchscreen |

| Materials | LDPE, LLDPE, HDPE, EVA |

Unmatched Versatility and Performance

The ABC Type SEPL Three Layer Blown Film Plant excels in diverse environments such as packaging industries, manufacturing units, and commercial spaces. With automatic operation, it guarantees consistent results for GP, PU, and LF usage types. Key features include a polished mild steel construction, high efficiency, and adaptable voltage compatibility, making it ideal for demanding applications that require continuous and dependable output.

Flexible Outlay Options and Strategic Market Presence

Customers can take advantage of favorable outlay rates with FOB Port handover options for seamless international trade. The machine is widely available across the main domestic market, ensuring easy order placement and fast delivery. Sample availability assures clients of quality, allowing them to evaluate performance before committing, ultimately offering a competitive edge to businesses seeking a strategic investment in film manufacturing technology.

FAQ's of ABC Type SEPL Three Layer Blown Film Plant:

Q: How does the ABC Type SEPL Three Layer Blown Film Plant enhance film production efficiency?

A: The plant's advanced three-layer blown film technology and automatic operations streamline the manufacturing process, delivering high outputs of up to 105 Kg/hr while maintaining consistent quality.Q: What applications are best suited for this machine?

A: This machine is ideal for producing films used in packaging, GP (General Purpose) films, PU (Polyurethane), and LF (Lamination Films), making it versatile for various industrial needs.Q: Where can the ABC Type SEPL Blown Film Plant be purchased or delivered?

A: It is available through exporters, manufacturers, and suppliers across India, with options for main domestic market delivery and international FOB Port handover for global clients.Q: What process is followed for sample availability?

A: Interested clients can request samples to evaluate the machine's quality and performance before finalizing their purchase, ensuring confidence in their investment.Q: What are the primary benefits of choosing this film plant?

A: The machine stands out for its reliability, high efficiency, robust mild steel construction, and flexibility in handling various voltages, making it a cost-effective and durable choice.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Blown Film Plant Category

SEPL Pro Monolayer Compact Blown Film Plant

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Power : 20 Horsepower (HP)

Features : Stable operation

Automatic Grade : Automatic

Usage & Applications : GP/PU

A-B And A-B-A Type SEPL Blown Film Plant

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Power : 10/20 Horsepower (HP)

Features : Stable operation

Automatic Grade : Automatic

Usage & Applications : GP/PU

SEPL Mini Monolayer Compact Blown Film Plant

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Power : 10 Horsepower (HP)

Features : Stable operation

Automatic Grade : Automatic

Usage & Applications : GP/PU

PP Blown Film Plan

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Power : 10 Horsepower (HP)

Features : Stable operation

Automatic Grade : Automatic

Usage & Applications : GP/PU

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese